Error de formato de correo electrónico

emailCannotEmpty

emailDoesExist

pwdLetterLimtTip

inconsistentPwd

pwdLetterLimtTip

inconsistentPwd

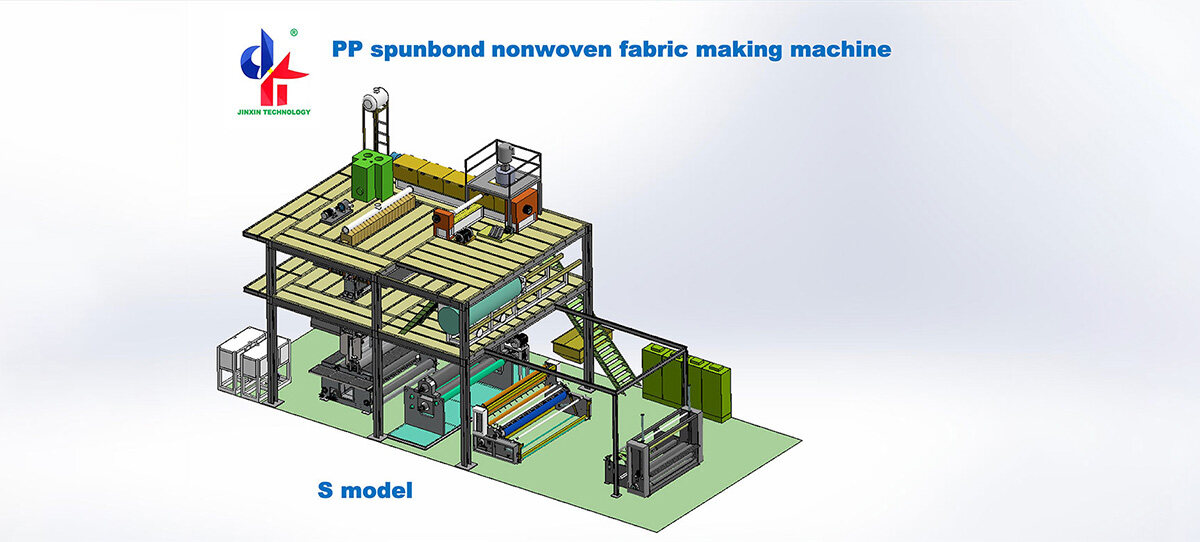

S nonwoven machine

The S Spunbond Nonwoven Machine uses a spinning drafting mechanism and an advanced electrical control cabinet. Advanced AC frequency-modulated speed and fully digital synchronized communications are elements of the system controlling mode. S Spunbond Nonwoven Machine has fewer investment requirements, a small footprint, a small covering area, and labor-saving capabilities.

| Model | JX-S | ||

|---|---|---|---|

| Product Width | 1600mm | 2400mm | 3200mm |

| Equipment Size | 20*10*12m | 20*10*12m | 20*12*12m |

| Mechanical Speed | 150m/min | 150m/min | 150m/min |

| Gram Weight | 10-200g/m2 | 10-200g/m2 | 10-200g/m2 |

| Daily Output | 4-6T/Day | 7-8T/Day | 9-10T/Day |

| Transformer Capacity | ≈200KVA | ≈250KVA | ≈315KVA |

| Power Consumption | 520°-650°Ton | 520°-650°Ton | 520°-650°Ton |

About Us

Fujian Jinxin Machinery Technology Co.,Ltd. was found in 2007.Our company offers variety of products which can meet your multifarious demands.We adhere to the management principles of "quality first, customer first and credit-based" and always do our best to satisfy potential needs of our customers.

We mainly produce S,SS,SSS,Meltblown,SMS,SSMS,SMMS,SSMMS,PLA,PET series nonwoven machine and laminating machine.

1.Medical: mask, protection gowns, bed sheets,drapes,shoe coves and etc.

2.Hygiene: children diaper, adult diaper, women care products and etc.

3.Packaging: shopping bags,clothes bags and etc

4.Other uses: crop protection cloth, tea bags , filter materials, lampshades, etc

Our Factory

Our product is quality proven,superior in design and produced as per the highest quality standards.Before leaving our factory,it is tested and retested for performance,productivity and durability.Through our continuous research and development, advanced skills, and a strong commitment to customer service,we are taken as a dependable supplier of China.No matter whether you are looking for a single machine or a whole production line,you can get outstanding machine and know-how results from us.Because of good quality and service,we have won a good reputation among domestic and international customers.

We hope to establish good and long-term business cooperation with customers all over the world. If you have any inquiries about our products, please feel free to contact us.

Product Features

1.S Spunbond Nonwoven Machine adopts an intelligent electrical control cabinet and spinning drafting system. The system controlling mode features in advanced AC frequency-modulated speed, and fully digital synchronized communications.

1.S Spunbond Nonwoven Machine is featured by lower investment, compact construction, small covering area, and labor-saving.

3. Spunbond Nonwoven Machine is a single-beam professional manufacturer of single-layer nonwoven fabric equipment which is manufactured for PP/PET/PLA/Bi-Component Spunbond nonwoven fabrics’ production. After the input of the raw materials, undergo the process of extrusion, spinning, quenching, closure air stretching, web formation, calendaring, winding, and cutting as per requirements and then packed for storage and delivery.

4.As the fabrics have great intensity, good breathability, and good feeling, they are widely used in various fields such as home decoration, furniture covers, clothing shoe leather, industrial and agricultural protective covers, medical and sanitary supplies, beauty products, and so on.

Product Application

Our S Spunbond Nonwoven Machines are designed and manufactured by individual customer requirements. Their possible area of application is correspondingly wide.

Such as :

PACKAGE – Shopping bag, Rice Packaging, Clothes packaging, etc.

HYGIENE – Baby and adult diapers, Female hygiene, etc.

MEDICAL – Surgeon’s masks, Disposable garments, etc.

FURNITURE – Beds Cover, Seatings Cover, etc.

TECHNICAL – Geotextiles, Agriculture, etc.

FILTRATION – Air, Gas, Liquids, etc.

BEDS: Pocket springs, mattresses, cushions, bed covers, disposal bedding, etc.

SEATING: Upholstered backs, sub-paneling, intermediate layers, etc.

Production Process

1.This production line use “slit negative pressure draft” technology.

2.Process flow: PP raw material Feeding → Extrusion Melting → Filtering → Metering → spinning → Cooling → Stretching → Web spreading → Thermal bonding → slitting → collecting.

Packing & Shipping

Standard export packaging:

1.Apply anti-rust oil to the equipment's easy rusty part and carry out the anti-rust treatment.

2.The whole machine was wrapped with stretch film for protection, and the equipment control cabinet and other components are protected against shock with packaging materials like XPS foam board and EPE foam sheet.

3.Reinforceeasy-move part of the equipment.

4.Put desiccant before packaging to avoid rusting equipment during sea transportation.